|

Home > Pebble Mine Information > Block CavingVideo illustrating block caving,

|

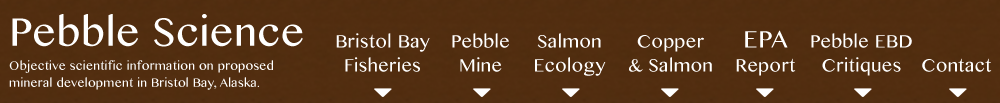

Figure 1. Pebble Deposit Cross Section (left).

The wedge of cover rocks (highlighted in green) |

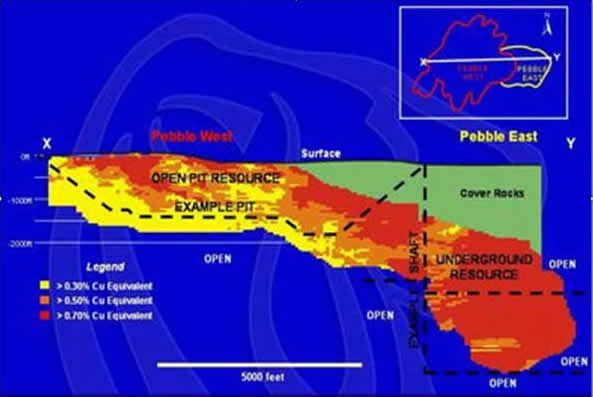

The Pebble Limited Partnership has proposed to mine Pebble East using the underground block caving method, which is the cheapest way to mine underground (Figure 2). It allows ore – economically valuable rock -- to collapse under its own weight in a controlled fashion.

|

| Figure 2. Block Caving Diagram (below). http://technology.infomine.com/reviews/Blockcaving/welcome.asp |

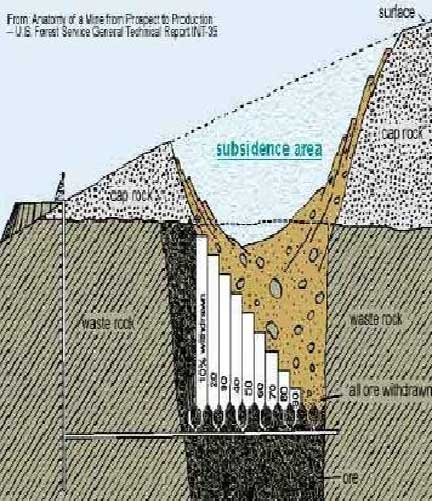

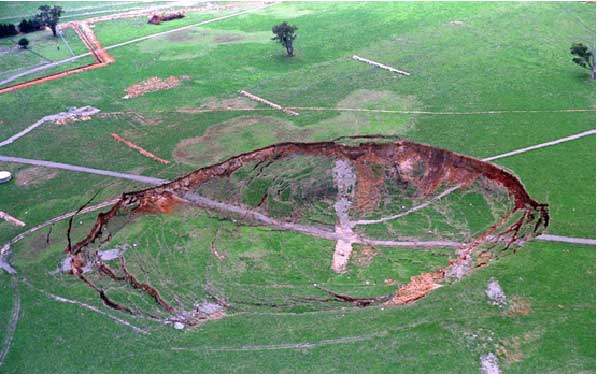

A series of haulage tunnels would be constructed under the ore to be mined. Between each tunnel a checkerboard pattern of interconnected side tunnels, or crosscuts, would allow easy movement throughout the site. Inclined slopes, known as raises, would connect the various levels. Large machines scrape the ore from below, letting it fall down to the main haulage tunnel below where it is removed for processing. As broken ore is removed, the capping or non-mineral bearing rock above the ore will gradually crack all the way to the surface, and large subsidence features typically form (Figures 3, 4).

|

Figure 3. Diagram of subsidence at an area mined by block caving (from Anatomy of a Mine from Prospect to Production, US Forest Service Report INT-35) |

|

Figure 4. Subsidence due to block caving at the Ridgeway Mine, New South Wales from Newcrest Ltd. Cadia Operations, available at http://en.wikipedia.org/wiki/Image:Elura.png#file |

SUBSIDENCE

The danger of block caving is that it removes much of the supporting rock from underneath the surface rock, often leading to subsidence, the gradual settling or sinking of the surface. Block caving typically results in large scale subsidence, and potential risks to humans, wildlife, and water quality.

WATER CONTAMINATION

Once the surface is ruptured, water can enter the underground mine from above. Instead of running off the surface, precipitation and surface water are directed to the mined area. Water percolating down through the rubble-rock remaining in the mine could lead to decomposition of the sulfide minerals and acid generation.

Some metals and metalloids are toxic to aquatic life in low concentrations. Toxic heavy metals in the rock from the decomposition of sulfide minerals (copper, zinc, lead, cadmium, or mercury) or metalloids (arsenic, selenium, thallium or antimony) can contaminate ground and surface waters far downstream from the mine. Migration of toxins off the mine site could be a long term problem.

This is an important potential long-term impact, and needs to be carefully researched and addressed. Block caving will most likely cause surface subsidence, and because the Pebble deposit is a sulfide deposit, the subsidence would result in generation of dangerous chemicals and their transport into the groundwater system.

This information is taken from “Block Caving,” a summary prepared by David Chambers, Ph.D., Center for Science in Public Participation, Bozeman, MT, March 2008 Available at www.pebblescience.org

1 http://www.northerndynastyminerals.com/ndm/Pebble.asp, June 12, 2007